SQE之评分系统(EXCEL格式)

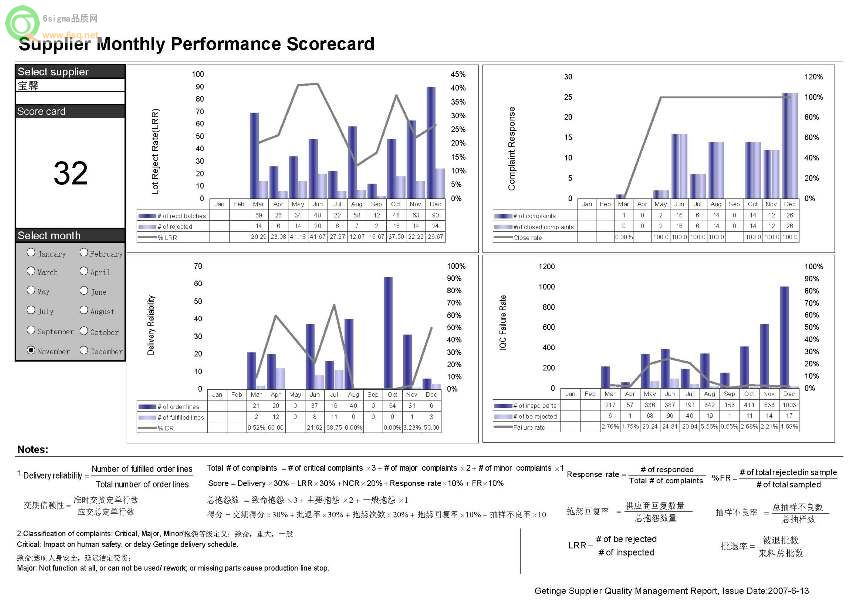

这个是我做的评分系统,评分公式如下:

分数 = 交期 30% + 批退率 30% + 投诉次数 20% + 投诉回复率 10% + IQC不良率 * 10% 均为量化评分,无主观因素(好坏不好说).

另外,本系统的所有密码都是 darcylee,密码的目的不是保护,是防止因误操作导致不良后果.

6 评价系统 Suppliers performance rating system

6.1 不良率 Failure rate

6.1.1 Here, we just count the total quantity of defects in sampling on IQC side, not include the defects found in production line.

这里,仅计IQC抽样数中的不良数量,不计产线不良.

6.2 批退率 Lot Reject Rate

6.3 抱怨Complaints

6.3.1 Complaints happen times in one month are also the emphasis of rating supplier performance. As the score distribution, please refer to bellow table.

Complaints (X) SCORE

X<1 1

1≤X<3 0.8

3≤X<5 0.6

5≤X<7 0.4

≥7 0

每月的抱怨发生次数也是XXXXX考察供应商的重点内容。一次都没有发生,满分;每月发生一次0.8分;两次到三次,0.6分;四次到六次0.4分;抱怨次数多余或等于7次时,0分。

抱怨发生次数 得分

X<1 1

1≤X<3 0.8

3≤X<5 0.6

5≤X<7 0.4

≥7 0

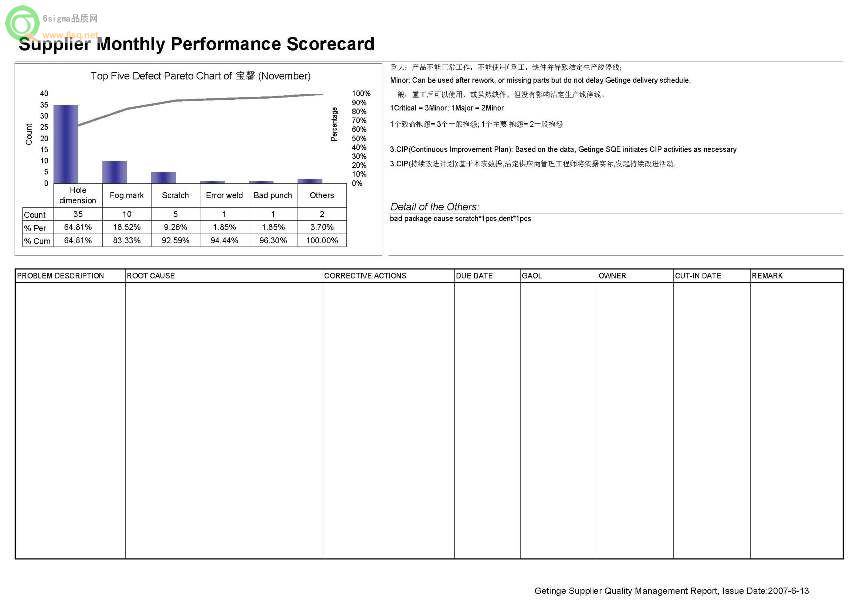

6.3.2 Classification of complains: Critical, Major, Minor

Critical: Impact on human safety, or delay XXXXX delivery schedule.

Major: Not function at all, or can not be used/ rework; or missing parts cause production line stop.

Minor: Can be used after rework, or missing parts but do not delay XXXXX delivery schedule.

抱怨等级定义:致命,重大,一般

致命:影响人身安全,延迟XXXXX交货;

重大:产品不能正常工作,不能使用/ 重工,缺件并导致XXXXX生产线停线;

一般:重工后可以使用,或虽然缺件,但没有影响XXXXX生产线停线。

6.3.3 1Critical = 3Minor; 1Major = 2Minor, the formula as below:

1个致命抱怨= 3个一般抱怨; 1个主要 抱怨= 2一般抱怨,计算公式如下:

6.3.4 Complaints happen times as an input parameter of XXXXX Supplier Rating System, the weight is 20%.

抱怨发生的次数作为XXXXX供应商评价系统的的一个输入参数,权重为20%。

6.4 抱怨回复率 Response rate

6.4.1 Service is also the emphasis of rating supplier performance. Main indictors of service are response time and response rate. XXXXX requirement is supplier should response within 24h after you received the NCR, submit the short term action. Supplier should submit the SCAR within two week.

供应商产品售后服务亦是XXXXX考察重要内容,XXXXX评价供应商服务水平的主要指标是NCR的回复速度和回复率,XXXXX要求,供应商应在接收到NCR后,在24小时回应短期处理方案,在两周内回复纠正措施。

6.4.2 Service as an input parameter of XXXXX Supplier Rating System, the weight is 10%.

服务作为XXXXX供应商评价系统的的一个输入参数,权重为10%。

Response rate Score

100.00% 1

80.00% 0.8

60.00% 0.6

40.00% 0.4

20.00% 0.2

0.00% 0

6.5 交期达成率Delivery reliability

6.5.1 Please remark XXXXX P.O., the quantity, supplier confirmed delivery date and COC report and relative information on your Delivery Note. If the information above mentioned missing, our Ware House Keeper will refuse to do receiving.

在递交货品时,请务必在DELIVERY NOTE上标明XXXXX定单,数量,供应商承诺交货日期,供应商出货品检验报告等信息,否则XXXXX仓库管理员将不予以收货。

6.5.2 XXXXX Call off will focus the DR of the every supplier. It is a very important parameter of XXXXX Supplier Rating System – Delivery Reliability. The weight of Delivery Reliability is 30%.

XXXXX采购将关注供应商交期达成率-XXXXX供应商管理评价系统的一个输入参数,供应商交期达成率在评价系统中的权重是30%.

XXXXX Delivery Reliability definition: Delivery before confirmed date. The formula as below:

XXXXX供应商交期达成定义是:在供应商承诺的交期内交货。

计算公式如下:

Delivery Reliability Score

100.00% 1

80.00% 0.8

60.00% 0.6

40.00% 0.4

20.00% 0.2

0.00% 0

6.6 评定系统Rating system

评分计算公式如下 Score calculation formula as below:

分数 = 交期 30% + 批退率 30% + 投诉次数 20% + 投诉回复率 10% + IQC不良率 * 10% 均为量化评分,无主观因素(好坏不好说).

另外,本系统的所有密码都是 darcylee,密码的目的不是保护,是防止因误操作导致不良后果.

6 评价系统 Suppliers performance rating system

6.1 不良率 Failure rate

6.1.1 Here, we just count the total quantity of defects in sampling on IQC side, not include the defects found in production line.

这里,仅计IQC抽样数中的不良数量,不计产线不良.

6.2 批退率 Lot Reject Rate

6.3 抱怨Complaints

6.3.1 Complaints happen times in one month are also the emphasis of rating supplier performance. As the score distribution, please refer to bellow table.

Complaints (X) SCORE

X<1 1

1≤X<3 0.8

3≤X<5 0.6

5≤X<7 0.4

≥7 0

每月的抱怨发生次数也是XXXXX考察供应商的重点内容。一次都没有发生,满分;每月发生一次0.8分;两次到三次,0.6分;四次到六次0.4分;抱怨次数多余或等于7次时,0分。

抱怨发生次数 得分

X<1 1

1≤X<3 0.8

3≤X<5 0.6

5≤X<7 0.4

≥7 0

6.3.2 Classification of complains: Critical, Major, Minor

Critical: Impact on human safety, or delay XXXXX delivery schedule.

Major: Not function at all, or can not be used/ rework; or missing parts cause production line stop.

Minor: Can be used after rework, or missing parts but do not delay XXXXX delivery schedule.

抱怨等级定义:致命,重大,一般

致命:影响人身安全,延迟XXXXX交货;

重大:产品不能正常工作,不能使用/ 重工,缺件并导致XXXXX生产线停线;

一般:重工后可以使用,或虽然缺件,但没有影响XXXXX生产线停线。

6.3.3 1Critical = 3Minor; 1Major = 2Minor, the formula as below:

1个致命抱怨= 3个一般抱怨; 1个主要 抱怨= 2一般抱怨,计算公式如下:

6.3.4 Complaints happen times as an input parameter of XXXXX Supplier Rating System, the weight is 20%.

抱怨发生的次数作为XXXXX供应商评价系统的的一个输入参数,权重为20%。

6.4 抱怨回复率 Response rate

6.4.1 Service is also the emphasis of rating supplier performance. Main indictors of service are response time and response rate. XXXXX requirement is supplier should response within 24h after you received the NCR, submit the short term action. Supplier should submit the SCAR within two week.

供应商产品售后服务亦是XXXXX考察重要内容,XXXXX评价供应商服务水平的主要指标是NCR的回复速度和回复率,XXXXX要求,供应商应在接收到NCR后,在24小时回应短期处理方案,在两周内回复纠正措施。

6.4.2 Service as an input parameter of XXXXX Supplier Rating System, the weight is 10%.

服务作为XXXXX供应商评价系统的的一个输入参数,权重为10%。

Response rate Score

100.00% 1

80.00% 0.8

60.00% 0.6

40.00% 0.4

20.00% 0.2

0.00% 0

6.5 交期达成率Delivery reliability

6.5.1 Please remark XXXXX P.O., the quantity, supplier confirmed delivery date and COC report and relative information on your Delivery Note. If the information above mentioned missing, our Ware House Keeper will refuse to do receiving.

在递交货品时,请务必在DELIVERY NOTE上标明XXXXX定单,数量,供应商承诺交货日期,供应商出货品检验报告等信息,否则XXXXX仓库管理员将不予以收货。

6.5.2 XXXXX Call off will focus the DR of the every supplier. It is a very important parameter of XXXXX Supplier Rating System – Delivery Reliability. The weight of Delivery Reliability is 30%.

XXXXX采购将关注供应商交期达成率-XXXXX供应商管理评价系统的一个输入参数,供应商交期达成率在评价系统中的权重是30%.

XXXXX Delivery Reliability definition: Delivery before confirmed date. The formula as below:

XXXXX供应商交期达成定义是:在供应商承诺的交期内交货。

计算公式如下:

Delivery Reliability Score

100.00% 1

80.00% 0.8

60.00% 0.6

40.00% 0.4

20.00% 0.2

0.00% 0

6.6 评定系统Rating system

评分计算公式如下 Score calculation formula as below:

没有找到相关结果

已邀请:

126 个回复

zhdablo

赞同来自: