【校稿】第四十八篇 The Pros of Proactive Product Servicing

本帖最后由 小编D 于 2012-3-22 14:31 编辑

你好,我是小编H。请对以下文章有校稿兴趣的组员留下你的预计完成时间和 邮箱,并发短信息联系小编H,以便小编登记翻译者信息以及文章最终完成时的奖惩工作。感谢支持翻译组!

本文翻译:xy_persist、dhjulia

ThePros of Proactive Product Servicing产品先期维护的理由

Monitoring maintenance helps avoid unexpected shutdowns实施监测维护将有利避免意外停工

By Necip Doganaksoy, Gerald J. Hahn andWilliam Q. Meeker作者:Nacip Doganaksoy, Gerald J. Hahn andWilliam Q. Meeker

Just as athlete scan experience an injurythat takes them out of a game, systems can experience component failures thatrequire downtime and repair.就像运动员仔细检查令他们退赛的伤痛,系统也应该对故障组件进行停机检查和修复。

We will describe three approaches1 that can minimize the cost, inconvenience orpotential danger of field failures through statistically based proactiveservicing (or just-in-time maintenance).下面我们来介绍三种可将现场故障的维修成本、引发的不便以及所带来的不良影响降到最低的,基于统计的主动性维修手段(准时制维护)。

A prime goal of proactive product servicingis to avoid unscheduled shutdowns. It is usually much less disruptive andcostly to perform repairs during scheduled maintenance on automobiles, aircraft engines, locomotivesand medical scanners, for example, than it is to deal with unexpected failuresin the field.产品先期维护的主要目的是避免计划外停机,在计划点检周期内进行点检,对生产造成的中断以及耗费成本都会比较小,比如汽车的定期保养、飞机的定期检修、医学扫描及检查设备的定期维护都是这样。

The emergence of long-term serviceagreements—manufacturers selling not just products, but also guaranteed ongoinglevels of service to customers—has further encouraged proactive servicing andincreased manufacturers’ desire to build high reliability into design in thefirst place.长期服务协议 ( 厂商出售产品之外,还需为客户提供产品运行阶段的质保服务)的出现,进一步促进了积极性维修的推行,同时大大提高了厂商首先考虑设计可靠性的意愿。

Even when a shutdown cannot be prevented,proactive servicing is still useful to ensure speedy, inexpensive repair, whichcan reduce the deleterious impact of such shutdowns.即使有些意外停工无法避免,也可以利用主动性维修来保证速度、降低维修成本以减少停工带来的消极影响

The three approaches for proactive productservicing are:主动性产品维修的三种手段包括:1. Optimum product maintenance scheduling.1.优化产品定期维护计划表2. Proactive parts replacement.2. 主动更换部件。3. Automated monitoring for impending failures.3.对可能发生的不良状况进行自动点检

Optimum product maintenance scheduling 制定最适宜的产品维护进度

Many systems, from automobiles to aircraft engines, areserviced periodically. Examples are automobile oil changes, scheduled thermalbarrier coating of turbine components and the replacement of filters in airconditioners.从汽车到飞机引擎,很多维护系统都是分时段运行的。例如,为汽车换油,定期更换涡轮部件的隔热涂层以及更换空调滤芯等

Routine maintenance should be scheduled to provide anoptimum trade-off between the cost and inconvenience of servicing, and thelikely greater cost and inconvenience due to unscheduled failures thatservicing could have averted.定期维护进度要有效地协调主动维修所带来的不便和成本与可能导致的计划外停工维修所耗费的不便和成本。

Consider an automobile maintenance scheduling example;similar considerations apply for other systems.以一个汽车维护进度为例,方法同样适用于其他的维护系统。

Automobile manufacturers traditionally advised buyers tochange oil and lubricate car parts every 3,000 miles. Using modern sensortechnology, however, automobile maintenance scheduling can be improved bytaking into account how the car is operated, considering factors such asdriving speed, number of stops and number of cold starts.汽车制造商一般会建议买主每3000英里更换机油以及给各部件补充润滑油。但是,采用现代传感技术,车的保养计划可以进行调整:现代传感技术可以采集车量行驶况,还可以综合考虑车速、停车次数以及冷启动次数。

Products used more harshly require more frequentservicing. This has led to the development of systems that determine thefrequency of routine maintenance based on driving and cost considerations.车辆使用条件越恶劣,就需要频率更高的保养。这就需要车厂提供综合考虑驾驶和维护费用的一般的保养周期。

Dynamic maintenance scheduling, or so-called condition-basedmaintenance (CBM),2 extends this concept.动态保养计划或称作以使用状况为基础的保养计划(CBM)有两个延伸的概念。

For automobiles, CBM might involve monitoring oildegradation and other measures of deterioration to determine the timing of thenext maintenance.对于汽车,CBM包括检查油品等级以及测试其它部件的品级状况来决定下一次保养时间。

The car operator is then advised, perhaps upon carstart-up, of the next recommended servicing.然后向车主提供下一次的推荐保养时间,比如说可能是车的启动。

Proactive parts replacement 准备好先期维护的备品备件

Many system field failures occur because relativelyinexpensive parts wear out, causing unscheduled shutdowns with costs that arefar greater than the cost of the part.很多系统发生故障是由于相对便宜的部件损坏,而它导致的非计划停机而发生的维修费用要比这个部件本身的成本高得多。

To avoid this, vulnerable parts should be replaced withnew ones at strategically selected times during routine maintenance.为了避免这些情况,在进行例行维护时直接挑选合适的时间更换易损件。

Sometimes, an impending failure can be detected by inspectingthe part or by embedded instrumentation, which we will address later.有时,我们在仔细检查某个部件或观察内置检测设备时会发现某些可能会发生的故障,这时我们就会着手进行处理。

In other cases, you need to rely on the estimatedstatistical lifetime distribution of the part for such assessment.还有一种情况,你需要根据某些部件使用寿命的统计学散布状况来评估保养周期。

If the hazard function for a part increases over time,the probability of failure of that part prior to the next (evenly spaced)scheduled maintenance also increases with time, and proactive replacementwarrants consideration.如果某一部件故障风险总是不断升高的话,那么它在下一次正常分布的保养期到来之前发生故障的概率也随之升高,那对于这一部件就更应该考虑先期维护了。

For example, this would be the case for a part with aWeibull distribution for its lifetime with a shape parameter exceedingone.3,4比如说,一个部件的使用寿命符合Weibull分布的形状,有一个参数超出了整个分布图的范围。

You might want to replace such parts during scheduledmaintenance if their estimated probability of failure prior to the nextscheduled maintenance exceeds a specified threshold, say one in 1,000, oralternatively, if this probability is twice its initial value.如果某些部件在下次保养前发生故障的概率超过某个特定值(比如说1000)或者其发生故障的概率为初始概率的2倍,你可能会在下次保养之前就想先更换这些零部件。

The specific plan needs to balance the cost ofprematurely replacing a part against the cost of its failure in service.特殊的保养计划需要平衡提前更换备件的费用和一旦发生故障时的维修费用。

The resulting statistical evaluations can again be mademore powerful by considering the operating environment.对于统计结果的评估应该更多的考虑车辆的行驶运行环境。

For example, in deciding when to replace a part in alocomotive, the analysis should consider the terrain (flat or mountainous) inwhich the locomotive will be operating.、比如说,如果想确定什么时候更换机车的零部件,就要考虑分析车辆的行驶的地形路况,是平地还是山地。

Automated monitoring for impending failures 将要发生故障的自动检测

Concept: A further strategy for avoiding or mitigating the impact of fieldfailures is provided by new technology: the remote, and often continuous, monitoringof products using sophisticated instrumentation. Car owners have becomeacquainted with this approach through lights flashing on their dashboards,which signal a possible reliability problem (for example, an impending enginemalfunction), safety concern (door not closed properly), environmental issue(emissions problem) or, sometimes, a false alarm (instrument malfunction).概念:避免或缓解现场故障影响的进一步策略可以采用以下新技术:远程控制、连续监测、采用精密设备进行监测。车主们已经熟悉仪表盘上各种指示灯所提示的各种问题,这些指示可能是信赖性问题(比如说,可能发生的发动机故障),安全隐患(车门未关好),环境问题(尾气排放),或者某些错误提示(检测仪故障)。

Forewarning of an impending system failure allows forrepairs in a minimally intrusive and cost-effective manner—ideally, withoutusers even being aware of the problem. At a minimum, it can help identify whatparts need to be replaced and the technical service personnel best suited toquickly make the repair.将要发生的系统故障的预先警示其实只需修复极小的故障,花费极低的费用而实现最有效的维护,这是用户可能还根本没有意识到将要发生的问题。至少,这能够帮助我们识别哪些部件需要更换,技术服务人员也能够迅速提供相应的服务进行维修。

Here’s a locomotive engine example: Modern locomotiveengines are equipped with numerous sensors that read operating parameters suchas oil pressure, oil temperature and water (coolant) temperature. The resultinginformation is used during normal operation to make automatic systemadjustments (for example, to control fuel and oil flow), using controlalgorithms.现在举一个发动机的例子:现在用的发动机装有很多传感器, 通过这些传感器能够读取运行参数,比如油压、油温和水(冷却)温。在正常运行过程中,这些测试结果信息可以让自动系统通过运算进行自动控制调节(比如说,保持燃油流动),

In addition, such data might be used to identify andavert impending failures by shutting down the system before serious damageoccurs. In light of the inconvenience and lost revenue associated withshutdowns, it is, however, imperative to minimize the number of false alarms sothe engine is shut down only when absolutely necessary.另外,这些数据可能被用来识别或者防止将要发生的故障,通过临时停机,系统就将不会出现更严重的损坏。然而,不考虑临时停机带来的不便和对财政支出造成的影响,仅在必要时停止发动机来减少故障报警是非常必要的。

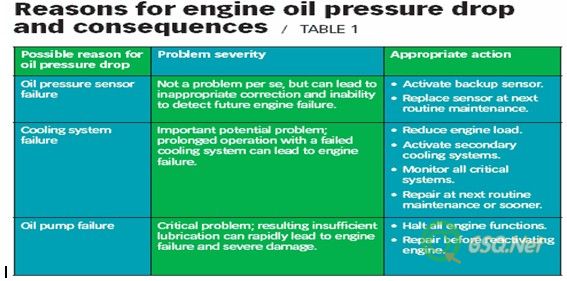

Failure modes: Consider the occurrence of an apparent large drop inengine oil pressure. This could be due to any of the three reasons shown inTable 1, together with the associated problem severity and the action thatwould be taken if it were known that this was, indeed, the reason for themeasured oil drop. These actions range from activating a back-up sensor toshutting down the engine.失效模式:发动机油压的明显大幅下降发生。这可能是由表1中三个原因的之一造成,综合考虑这些问题细部分解,如果知道哪个是导致问题发生的原因,就可以采取相应的措施来记录油压下降。这一系列措施会激活一根备用传感器来使发动机停止工作。

Thus, when an oil pressure drop is indicated,we need to find the reason so we can take the appropriate action. Sensor dataon how oil pressure—and oil and water temperature—are changing over time canhelp make this determination.综上所述,当发现油压偏低时,我们应该立刻找出原因并采取有效的应对措施。通过读取传感器的数据来获知油压(和油温、水温)的浮动变化,并作出反应。 Data acquisition: Each of the threemeasured oil pressure drop modes shown in Table 1 were induced in a lab test toobserve the resulting sensor measurements. Figure 1 shows the readings on threesensors—monitoring oil pressure, oil temperature and water temperature—over a30-second time period. The solid triangle marks the point at which the problemwas induced, as evidenced by an appreciable change in one or more of the threemeasurements.数据采集: 针对表一中列出的三个油压过低模式分别进行实验,以观察相应感应设备的工作。三个感应器(监测油压、油温和水温)持续30秒内的读数见附图一。当其中的一个或者多个变量产生变化时所产生的问题分别见实心小三角标注的各点。 Analysis: Each of the threeincidents resulted in a sudden, sharp drop in the reading for oil pressure. Theaccompanying changes in oil temperature and water temperature readings,however, differed. Thus, data from the three sensors might help distinguishamong the three possible reasons for the apparent oil pressure drop:分析:三种问题的产生都会引发油压传感器读数骤降,此时油温和水温感应器读数也会随之产生不同的变化。因此,三个传感器的读数可以帮助区分引起油压骤降的三个主要诱因。

Toward analgorithm: The data in Figure 1 were from a single engine underfixed test conditions in a lab. Similar data were obtained on different enginesoperating in the field under varying environments and involving various oil pressuredrop incidents.

关于算法:图1中的数据来自于单一发动机固定条件的试验室测试结果。另外还在不同的运行环境以及不同的油压突然下降的突发情况下得到了类似的现场应用数据。

Results in exampleThe resulting patterns were sufficientlydistinct and similar to those depicted in Figure 1to develop a useful algorithmfor the three sensor (and some further) measurements to identify the reason fora drop in the measured oil pressure. This led, in a great majority of cases, toappropriate remedial action, including the all-important decision of whether ornot to shut down the system.

例子中的结果:计算的结果模型能够完全将三个传感器采集的数据进行分离就像图1中描述的那样,建立有效的模型来分析三根传感器(将来可能更多)测量的数据来区分油压下降的原因。大多数情况下,根据分析结果能够采取补救措施包括作出重要的决策:判断是否应该马上切断系统。

The analyses requiredthe use of advanced multivariate5 andtime series6 methods.Various other analytic methods are also used in automated monitoring forimpending failures, including machine learning, neural nets and Bayesian beliefnetworks.7, 8

分析需要采用先进的多元设备和时间序列法,在自动检测将要发生故障的检测系统中还要采用多种分析方法,包括机器学习、神经网络和贝叶斯信任网络。

Statistical methodsplay an important part in proactive product servicing. Such work, as always, isconducted in collaboration with knowledgeable engineers and subject matterexperts.

统计方法在主动性产品维修中起到了不可或缺的作用。 相关内容经常见诸于各大著名工程师及学术专家的著作中。

Necip Doganaksoy is a statistician and Six Sigma Master BlackBelt at the GE Global Research Center in Schenectady, NY. He has a doctorate inadministrative and engineering systems from UnionCollege in Schenectady. Doganaksoy is a fellow of ASQand the American Statistical Association.

Necip Doganaksoy统计学家,通用纽约斯克内克塔迪的全球研发中心六西格玛黑带大师。拥有纽约斯克内克塔迪联合学院的管理工程系统专业博士学位。是美国质量协会(ASQ)和美国统计协会会员。

Gerald J. Hahn is aretired manager of statistics at the GE Global Research Center in Schenectady, NY.He has a doctorate in statistics and operations research from RensselaerPolytechnic Institute in Troy, NY. Hahn is a fellow of ASQ andthe American Statistical Association.

Gerald J. Hahn曾任通用纽约斯克内克塔迪全球研发中心统计分析主要负责人,现已退休。拥有纽约特洛伊的伦斯勒理工学院统计学和运筹学博士学位。

是美国质量协会(ASQ)和美国统计协会会员。

William Q. Meeker isprofessor of statistics and distinguished professor of liberal arts andsciences at Iowa StateUniversity in Ames, IA. Hehas a doctorate in administrative and engineering systems from Union Collegein Schenectady, NY. Meeker is a fellow of ASQ and theAmerican Statistical Association.

William Q. Meeker

统计学专家,现任美国爱荷华州立大学自由艺术与科学院特聘教授。拥有纽约斯克内克塔迪联合学院的管理工程系统专业博士学位。是美国质量协会(ASQ)和美国统计协会会员。

你好,我是小编H。请对以下文章有校稿兴趣的组员留下你的预计完成时间和 邮箱,并发短信息联系小编H,以便小编登记翻译者信息以及文章最终完成时的奖惩工作。感谢支持翻译组!

本文翻译:xy_persist、dhjulia

ThePros of Proactive Product Servicing产品先期维护的理由

Monitoring maintenance helps avoid unexpected shutdowns实施监测维护将有利避免意外停工

By Necip Doganaksoy, Gerald J. Hahn andWilliam Q. Meeker作者:Nacip Doganaksoy, Gerald J. Hahn andWilliam Q. Meeker

Just as athlete scan experience an injurythat takes them out of a game, systems can experience component failures thatrequire downtime and repair.就像运动员仔细检查令他们退赛的伤痛,系统也应该对故障组件进行停机检查和修复。

We will describe three approaches1 that can minimize the cost, inconvenience orpotential danger of field failures through statistically based proactiveservicing (or just-in-time maintenance).下面我们来介绍三种可将现场故障的维修成本、引发的不便以及所带来的不良影响降到最低的,基于统计的主动性维修手段(准时制维护)。

A prime goal of proactive product servicingis to avoid unscheduled shutdowns. It is usually much less disruptive andcostly to perform repairs during scheduled maintenance on automobiles, aircraft engines, locomotivesand medical scanners, for example, than it is to deal with unexpected failuresin the field.产品先期维护的主要目的是避免计划外停机,在计划点检周期内进行点检,对生产造成的中断以及耗费成本都会比较小,比如汽车的定期保养、飞机的定期检修、医学扫描及检查设备的定期维护都是这样。

The emergence of long-term serviceagreements—manufacturers selling not just products, but also guaranteed ongoinglevels of service to customers—has further encouraged proactive servicing andincreased manufacturers’ desire to build high reliability into design in thefirst place.长期服务协议 ( 厂商出售产品之外,还需为客户提供产品运行阶段的质保服务)的出现,进一步促进了积极性维修的推行,同时大大提高了厂商首先考虑设计可靠性的意愿。

Even when a shutdown cannot be prevented,proactive servicing is still useful to ensure speedy, inexpensive repair, whichcan reduce the deleterious impact of such shutdowns.即使有些意外停工无法避免,也可以利用主动性维修来保证速度、降低维修成本以减少停工带来的消极影响

The three approaches for proactive productservicing are:主动性产品维修的三种手段包括:1. Optimum product maintenance scheduling.1.优化产品定期维护计划表2. Proactive parts replacement.2. 主动更换部件。3. Automated monitoring for impending failures.3.对可能发生的不良状况进行自动点检

Optimum product maintenance scheduling 制定最适宜的产品维护进度

Many systems, from automobiles to aircraft engines, areserviced periodically. Examples are automobile oil changes, scheduled thermalbarrier coating of turbine components and the replacement of filters in airconditioners.从汽车到飞机引擎,很多维护系统都是分时段运行的。例如,为汽车换油,定期更换涡轮部件的隔热涂层以及更换空调滤芯等

Routine maintenance should be scheduled to provide anoptimum trade-off between the cost and inconvenience of servicing, and thelikely greater cost and inconvenience due to unscheduled failures thatservicing could have averted.定期维护进度要有效地协调主动维修所带来的不便和成本与可能导致的计划外停工维修所耗费的不便和成本。

Consider an automobile maintenance scheduling example;similar considerations apply for other systems.以一个汽车维护进度为例,方法同样适用于其他的维护系统。

Automobile manufacturers traditionally advised buyers tochange oil and lubricate car parts every 3,000 miles. Using modern sensortechnology, however, automobile maintenance scheduling can be improved bytaking into account how the car is operated, considering factors such asdriving speed, number of stops and number of cold starts.汽车制造商一般会建议买主每3000英里更换机油以及给各部件补充润滑油。但是,采用现代传感技术,车的保养计划可以进行调整:现代传感技术可以采集车量行驶况,还可以综合考虑车速、停车次数以及冷启动次数。

Products used more harshly require more frequentservicing. This has led to the development of systems that determine thefrequency of routine maintenance based on driving and cost considerations.车辆使用条件越恶劣,就需要频率更高的保养。这就需要车厂提供综合考虑驾驶和维护费用的一般的保养周期。

Dynamic maintenance scheduling, or so-called condition-basedmaintenance (CBM),2 extends this concept.动态保养计划或称作以使用状况为基础的保养计划(CBM)有两个延伸的概念。

For automobiles, CBM might involve monitoring oildegradation and other measures of deterioration to determine the timing of thenext maintenance.对于汽车,CBM包括检查油品等级以及测试其它部件的品级状况来决定下一次保养时间。

The car operator is then advised, perhaps upon carstart-up, of the next recommended servicing.然后向车主提供下一次的推荐保养时间,比如说可能是车的启动。

Proactive parts replacement 准备好先期维护的备品备件

Many system field failures occur because relativelyinexpensive parts wear out, causing unscheduled shutdowns with costs that arefar greater than the cost of the part.很多系统发生故障是由于相对便宜的部件损坏,而它导致的非计划停机而发生的维修费用要比这个部件本身的成本高得多。

To avoid this, vulnerable parts should be replaced withnew ones at strategically selected times during routine maintenance.为了避免这些情况,在进行例行维护时直接挑选合适的时间更换易损件。

Sometimes, an impending failure can be detected by inspectingthe part or by embedded instrumentation, which we will address later.有时,我们在仔细检查某个部件或观察内置检测设备时会发现某些可能会发生的故障,这时我们就会着手进行处理。

In other cases, you need to rely on the estimatedstatistical lifetime distribution of the part for such assessment.还有一种情况,你需要根据某些部件使用寿命的统计学散布状况来评估保养周期。

If the hazard function for a part increases over time,the probability of failure of that part prior to the next (evenly spaced)scheduled maintenance also increases with time, and proactive replacementwarrants consideration.如果某一部件故障风险总是不断升高的话,那么它在下一次正常分布的保养期到来之前发生故障的概率也随之升高,那对于这一部件就更应该考虑先期维护了。

For example, this would be the case for a part with aWeibull distribution for its lifetime with a shape parameter exceedingone.3,4比如说,一个部件的使用寿命符合Weibull分布的形状,有一个参数超出了整个分布图的范围。

You might want to replace such parts during scheduledmaintenance if their estimated probability of failure prior to the nextscheduled maintenance exceeds a specified threshold, say one in 1,000, oralternatively, if this probability is twice its initial value.如果某些部件在下次保养前发生故障的概率超过某个特定值(比如说1000)或者其发生故障的概率为初始概率的2倍,你可能会在下次保养之前就想先更换这些零部件。

The specific plan needs to balance the cost ofprematurely replacing a part against the cost of its failure in service.特殊的保养计划需要平衡提前更换备件的费用和一旦发生故障时的维修费用。

The resulting statistical evaluations can again be mademore powerful by considering the operating environment.对于统计结果的评估应该更多的考虑车辆的行驶运行环境。

For example, in deciding when to replace a part in alocomotive, the analysis should consider the terrain (flat or mountainous) inwhich the locomotive will be operating.、比如说,如果想确定什么时候更换机车的零部件,就要考虑分析车辆的行驶的地形路况,是平地还是山地。

Automated monitoring for impending failures 将要发生故障的自动检测

Concept: A further strategy for avoiding or mitigating the impact of fieldfailures is provided by new technology: the remote, and often continuous, monitoringof products using sophisticated instrumentation. Car owners have becomeacquainted with this approach through lights flashing on their dashboards,which signal a possible reliability problem (for example, an impending enginemalfunction), safety concern (door not closed properly), environmental issue(emissions problem) or, sometimes, a false alarm (instrument malfunction).概念:避免或缓解现场故障影响的进一步策略可以采用以下新技术:远程控制、连续监测、采用精密设备进行监测。车主们已经熟悉仪表盘上各种指示灯所提示的各种问题,这些指示可能是信赖性问题(比如说,可能发生的发动机故障),安全隐患(车门未关好),环境问题(尾气排放),或者某些错误提示(检测仪故障)。

Forewarning of an impending system failure allows forrepairs in a minimally intrusive and cost-effective manner—ideally, withoutusers even being aware of the problem. At a minimum, it can help identify whatparts need to be replaced and the technical service personnel best suited toquickly make the repair.将要发生的系统故障的预先警示其实只需修复极小的故障,花费极低的费用而实现最有效的维护,这是用户可能还根本没有意识到将要发生的问题。至少,这能够帮助我们识别哪些部件需要更换,技术服务人员也能够迅速提供相应的服务进行维修。

Here’s a locomotive engine example: Modern locomotiveengines are equipped with numerous sensors that read operating parameters suchas oil pressure, oil temperature and water (coolant) temperature. The resultinginformation is used during normal operation to make automatic systemadjustments (for example, to control fuel and oil flow), using controlalgorithms.现在举一个发动机的例子:现在用的发动机装有很多传感器, 通过这些传感器能够读取运行参数,比如油压、油温和水(冷却)温。在正常运行过程中,这些测试结果信息可以让自动系统通过运算进行自动控制调节(比如说,保持燃油流动),

In addition, such data might be used to identify andavert impending failures by shutting down the system before serious damageoccurs. In light of the inconvenience and lost revenue associated withshutdowns, it is, however, imperative to minimize the number of false alarms sothe engine is shut down only when absolutely necessary.另外,这些数据可能被用来识别或者防止将要发生的故障,通过临时停机,系统就将不会出现更严重的损坏。然而,不考虑临时停机带来的不便和对财政支出造成的影响,仅在必要时停止发动机来减少故障报警是非常必要的。

Failure modes: Consider the occurrence of an apparent large drop inengine oil pressure. This could be due to any of the three reasons shown inTable 1, together with the associated problem severity and the action thatwould be taken if it were known that this was, indeed, the reason for themeasured oil drop. These actions range from activating a back-up sensor toshutting down the engine.失效模式:发动机油压的明显大幅下降发生。这可能是由表1中三个原因的之一造成,综合考虑这些问题细部分解,如果知道哪个是导致问题发生的原因,就可以采取相应的措施来记录油压下降。这一系列措施会激活一根备用传感器来使发动机停止工作。

Thus, when an oil pressure drop is indicated,we need to find the reason so we can take the appropriate action. Sensor dataon how oil pressure—and oil and water temperature—are changing over time canhelp make this determination.综上所述,当发现油压偏低时,我们应该立刻找出原因并采取有效的应对措施。通过读取传感器的数据来获知油压(和油温、水温)的浮动变化,并作出反应。 Data acquisition: Each of the threemeasured oil pressure drop modes shown in Table 1 were induced in a lab test toobserve the resulting sensor measurements. Figure 1 shows the readings on threesensors—monitoring oil pressure, oil temperature and water temperature—over a30-second time period. The solid triangle marks the point at which the problemwas induced, as evidenced by an appreciable change in one or more of the threemeasurements.数据采集: 针对表一中列出的三个油压过低模式分别进行实验,以观察相应感应设备的工作。三个感应器(监测油压、油温和水温)持续30秒内的读数见附图一。当其中的一个或者多个变量产生变化时所产生的问题分别见实心小三角标注的各点。 Analysis: Each of the threeincidents resulted in a sudden, sharp drop in the reading for oil pressure. Theaccompanying changes in oil temperature and water temperature readings,however, differed. Thus, data from the three sensors might help distinguishamong the three possible reasons for the apparent oil pressure drop:分析:三种问题的产生都会引发油压传感器读数骤降,此时油温和水温感应器读数也会随之产生不同的变化。因此,三个传感器的读数可以帮助区分引起油压骤降的三个主要诱因。

- For the faulty sensor, the drop in theoil pressure reading was not accompanied by any discernible change in eitheroil or water temperature.1. 感应器失效:油压感应器读数偏低,但是油温水温感应器皆无异常显示。

- For the cooling system failure, a sharp rise in watertemperature preceded the drop in measured oil pressure, which was alsoaccompanied by a sharp rise in oil temperature.2. 冷却系统失效:水温、油温传感器读数骤升。

- For the oil pump failure, a sharp rise in oil temperaturefollowed the drop in measured oil pressure. Water temperature remainedunchanged.3. 油泵失效:油温传感器读数骤升,油压传感器读数骤降,水温传感器读数不变。

Toward analgorithm: The data in Figure 1 were from a single engine underfixed test conditions in a lab. Similar data were obtained on different enginesoperating in the field under varying environments and involving various oil pressuredrop incidents.

关于算法:图1中的数据来自于单一发动机固定条件的试验室测试结果。另外还在不同的运行环境以及不同的油压突然下降的突发情况下得到了类似的现场应用数据。

Results in exampleThe resulting patterns were sufficientlydistinct and similar to those depicted in Figure 1to develop a useful algorithmfor the three sensor (and some further) measurements to identify the reason fora drop in the measured oil pressure. This led, in a great majority of cases, toappropriate remedial action, including the all-important decision of whether ornot to shut down the system.

例子中的结果:计算的结果模型能够完全将三个传感器采集的数据进行分离就像图1中描述的那样,建立有效的模型来分析三根传感器(将来可能更多)测量的数据来区分油压下降的原因。大多数情况下,根据分析结果能够采取补救措施包括作出重要的决策:判断是否应该马上切断系统。

The analyses requiredthe use of advanced multivariate5 andtime series6 methods.Various other analytic methods are also used in automated monitoring forimpending failures, including machine learning, neural nets and Bayesian beliefnetworks.7, 8

分析需要采用先进的多元设备和时间序列法,在自动检测将要发生故障的检测系统中还要采用多种分析方法,包括机器学习、神经网络和贝叶斯信任网络。

Statistical methodsplay an important part in proactive product servicing. Such work, as always, isconducted in collaboration with knowledgeable engineers and subject matterexperts.

统计方法在主动性产品维修中起到了不可或缺的作用。 相关内容经常见诸于各大著名工程师及学术专家的著作中。

Necip Doganaksoy is a statistician and Six Sigma Master BlackBelt at the GE Global Research Center in Schenectady, NY. He has a doctorate inadministrative and engineering systems from UnionCollege in Schenectady. Doganaksoy is a fellow of ASQand the American Statistical Association.

Necip Doganaksoy统计学家,通用纽约斯克内克塔迪的全球研发中心六西格玛黑带大师。拥有纽约斯克内克塔迪联合学院的管理工程系统专业博士学位。是美国质量协会(ASQ)和美国统计协会会员。

Gerald J. Hahn is aretired manager of statistics at the GE Global Research Center in Schenectady, NY.He has a doctorate in statistics and operations research from RensselaerPolytechnic Institute in Troy, NY. Hahn is a fellow of ASQ andthe American Statistical Association.

Gerald J. Hahn曾任通用纽约斯克内克塔迪全球研发中心统计分析主要负责人,现已退休。拥有纽约特洛伊的伦斯勒理工学院统计学和运筹学博士学位。

是美国质量协会(ASQ)和美国统计协会会员。

William Q. Meeker isprofessor of statistics and distinguished professor of liberal arts andsciences at Iowa StateUniversity in Ames, IA. Hehas a doctorate in administrative and engineering systems from Union Collegein Schenectady, NY. Meeker is a fellow of ASQ and theAmerican Statistical Association.

William Q. Meeker

统计学专家,现任美国爱荷华州立大学自由艺术与科学院特聘教授。拥有纽约斯克内克塔迪联合学院的管理工程系统专业博士学位。是美国质量协会(ASQ)和美国统计协会会员。

没有找到相关结果

已邀请:

3 个回复

Nida_gutt (威望:1) (江苏 苏州) 机械制造 主管

赞同来自:

我初步看了一眼,有的专业方面翻译不是很到位,需要修订。 可能和翻译的专业知识有关。

但是本人比较忙,可需要一些时间。十天左右交。12月15日前。